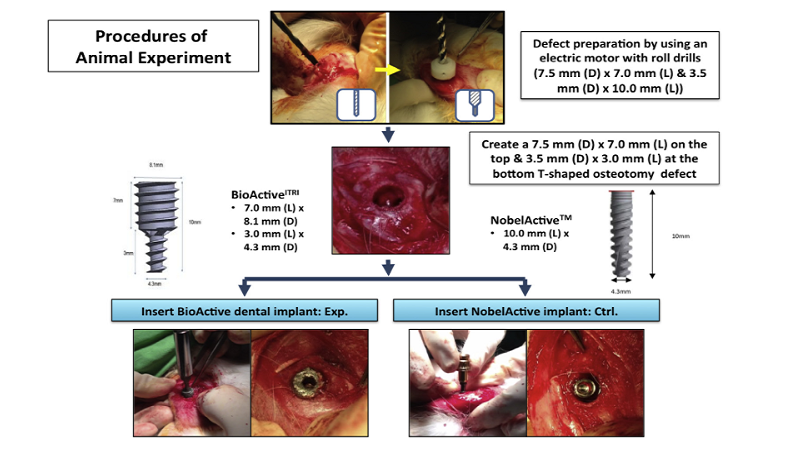

Researchers from Taiwan worked on improved methods of accommodating bone defects after failed implants must be removed using 3D Printing. Bio-Active Dental implant, which were manufactured with laser-sintered additive 3D printing technique, were used in animal experiments where one side of distal femurs was randomly selected for the commercially pure titanium NobelActive implant (control group) and the other side with Bio-Active Ti6Al4V porous dental implant (ITRI group). After Bio-printing with EOSINT M 280 system, the researchers concluded that by enlarging pore width at the nanoscale, they can to increase bioactivity features as well as accelerate osseogenesis during Dental Surgeries.

Read More: https://www.sciencedirect.com/science/article/pii/S0929664619305157